Ringbrothers “enyo” 1948 Chevrolet Super Truck

The most extreme Ringbrothers build yet merges vintage farm truck with a modern racecar and boast a high-performance 1,000-horsepower tall-deck marine racing engine and hundreds of custom touches attained through over 10,000 build hours of craftsmanship and finish work.

Photos by David Heller

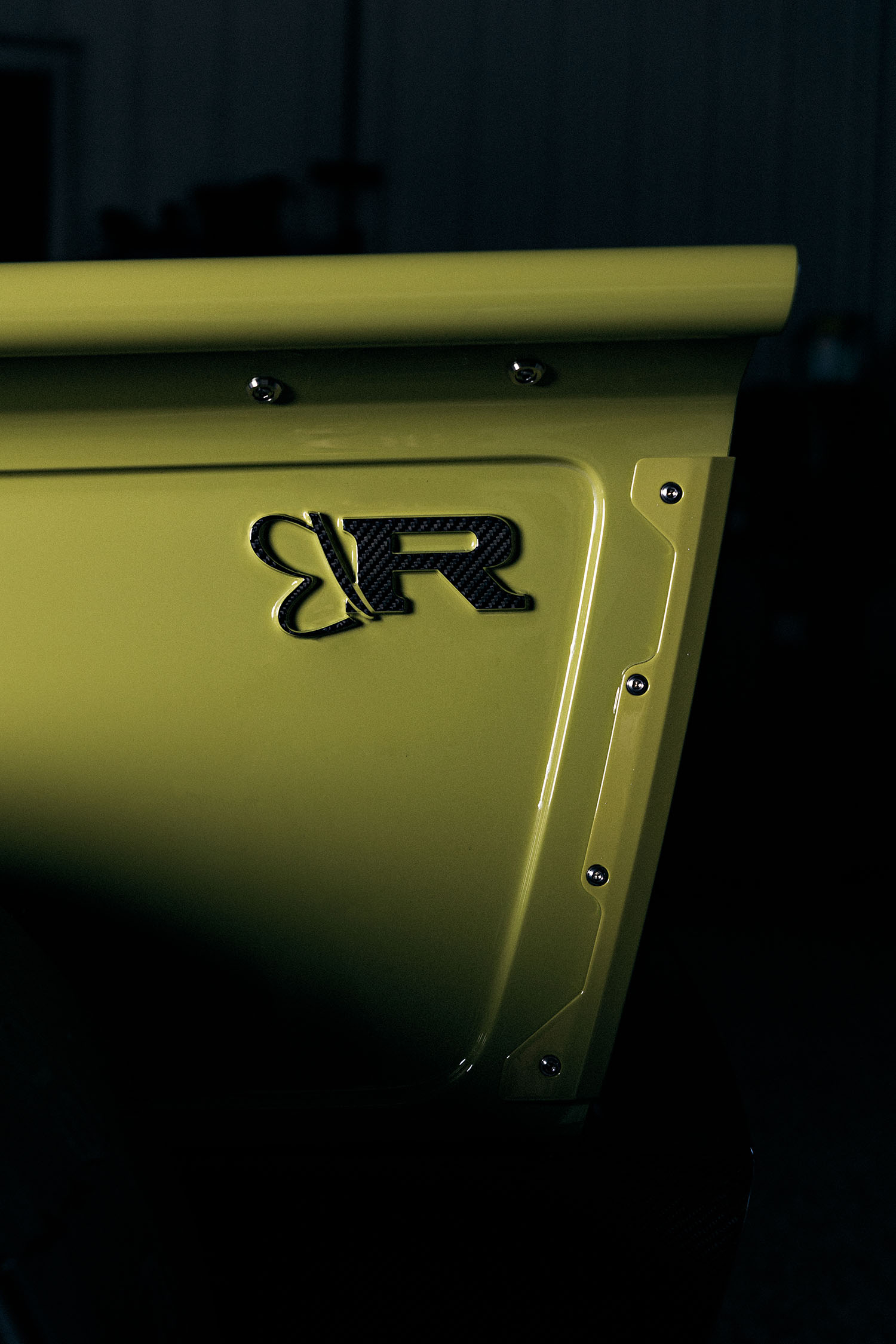

Ringbrothers, the world-renowned custom car builder and parts manufacturer, has unveiled its most extreme creation yet, the ENYO super truck. The new build is paradoxical to traditional American truck capabilities. The 1948 Chevrolet Pickup results from over 10,000 thorough and laborious build hours. Also, powered by a Goodwin 1,000-horsepower tall-deck racing engine and crafted using extensive carbon-fibre components, ENYO embodies the quality and custom work Ringbrothers is known for.Ringbrothers is in new territory with four vehicle debuts at this years SEMA Show, said Ringbrothers co-owner Mike Ring. But we are especially excited to share ENYO with the world as our most outrageous build yet. This long-term project really showcases our ability to explore new means of design, engineering and performance within an entirely new realm of challenges and production with our partners. So, the outcome speaks for itself.

After several years of planning and finding the right customer to commission the build, Ringbrothers turned the pipe dream of building an anti-street-rod into a reality. The chopped channelled and sectioned 1948 Chevrolet pickup redefines the American classic with performance and design aspects that were inconceivable in its original era.

ENYO features state-of-the-art chassis and suspension design, carbon fibre parts and aero management with wings and splitters that pushed Ringbrothers and the build partners into new territory. Unlike anything ever applied to a hot rod before, ENYO has incredible details baked in. From the CAD-designed trim and parts that were all cut in-house at the Ringbrothers machining facility to the way they seamlessly managed to mate a big-box truck cab and massive drivetrain successfully on a low-slung, open-wheeled, car-style chassis.

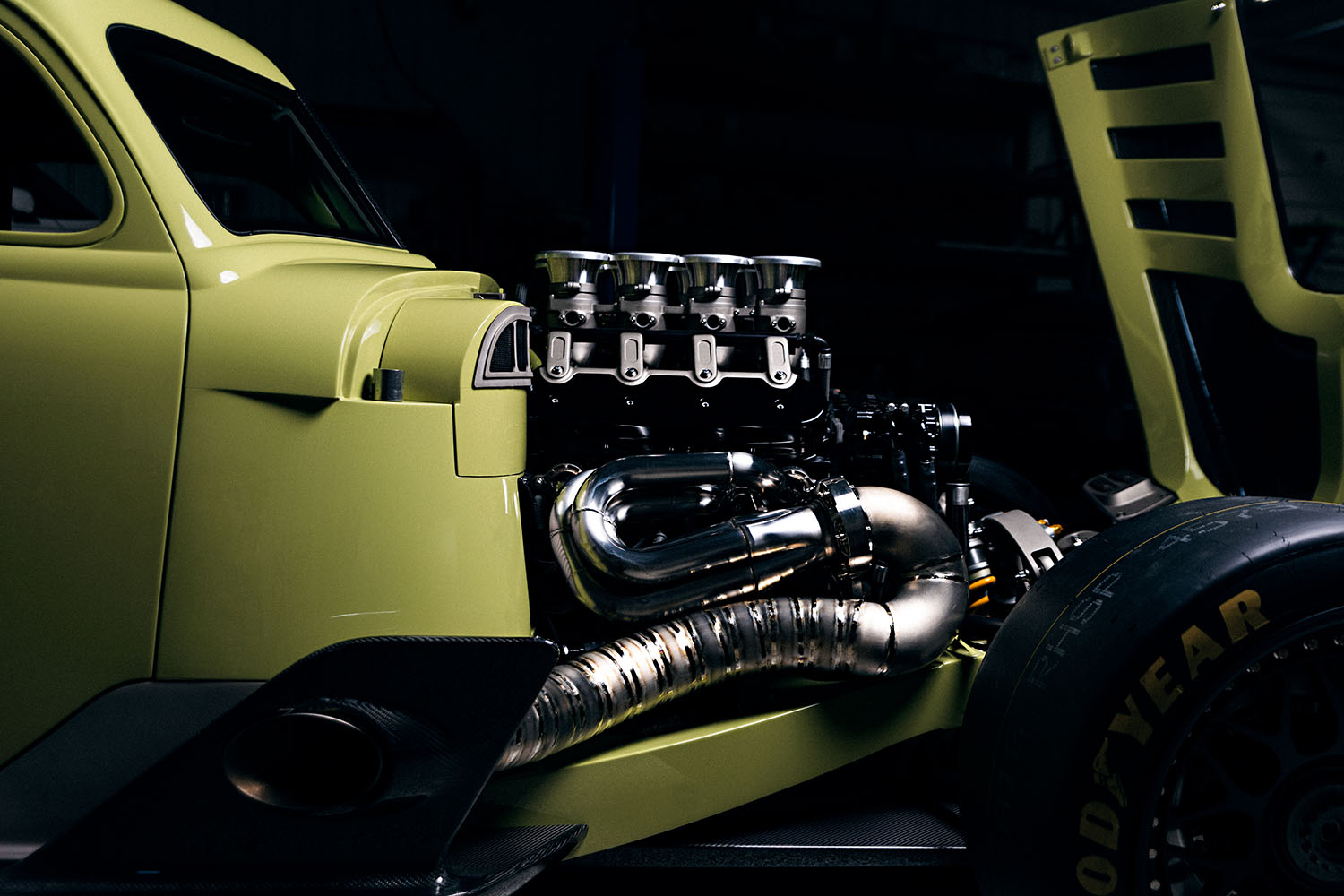

We have been quietly planning this build for years, imagining and reimagining how it would ultimately take shape, said Ringbrothers co-owner Jim Ring. The end result is truly a super truck that brings together two vehicles that should never have met. All this, to deliver immense character combined with power and performance that is usually reserved fortodays most advanced racecars. Were thrilled to be able to share ENYO with the world finally.The racing-inspired drivetrain is equipped with a 510 cubic-inch tall-deck engine built by Todd Goodwin producing 1,000 horsepower with Kinsler eight-stack injection. Also, a Holley fuel management system and a Bowler Performance Corvette torque-tube 4L80 automatic transaxle.

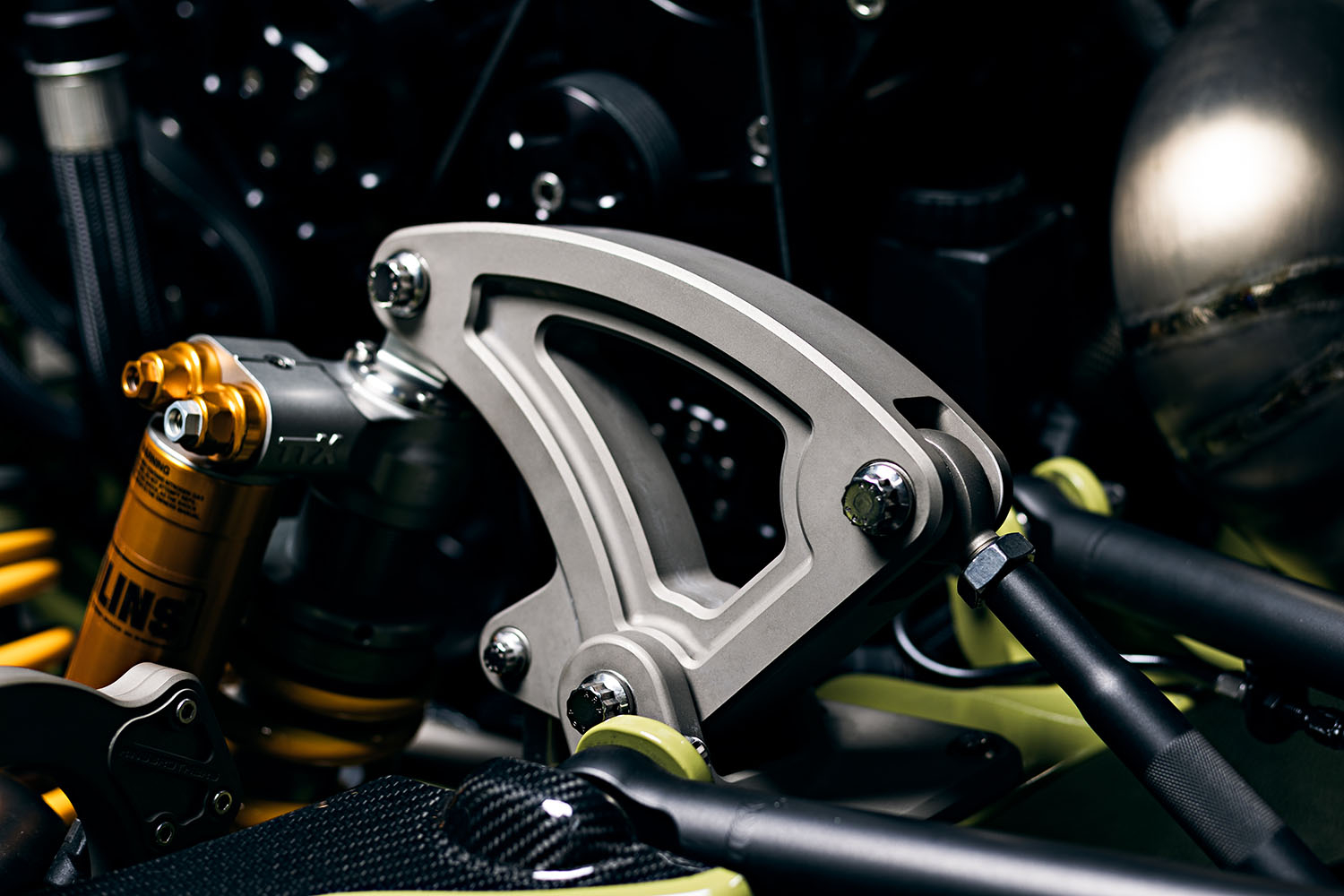

ENYO features a cantilever-independent suspension at all four corners with Ohlins shocks to ensure the massive power is transferred to the ground for maximum grip and performance. The open-wheeled truck sits on custom Porsche 911 pin-drive wheels by HRE Wheels. Furthermore, both track and street wheels are included with the installed Nuke Performance air jack system facilitating quick swaps. Big Brembo GTS M6 brakes with six-piston callipers provide stopping power.

Atop the one-off chassis designed by Scott Ahlman, Ahlman Engineering, in conjunction with Roadster Shop is the original 1948 steel cab extensively modified by Ringbrothers. Through careful craftsmanship, it is narrowed and chopped by four inches, lengthened and wedge cut. The remaining body pieces are constructed in 3K-weave carbon fibre, including a single-piece carbon-fibre belly pan spanning from front to back.

ENYOs modernization doesnt stop at its engine. Furthermore, Ringbrothers implemented power windows, a custom stainless-steel gas tank by Ricks Tanks, and a Vintage Air Gen II compact air-conditioning system. Finally, also a custom interior collaboration with Upholstery Unlimited and Gemini Technology Systems.

The open truck bed stages all the components needed to run this beast, and the clamshell hood is easily opened with electromagnetic latches. The side pipes are made from 58 feet of titanium pie-cut welds and are connected to the shining one-off custom headers. Therefore, every part of ENYO is created to show its impeccable design and performance capabilities.As leaders in their industry, Mike and Jim Ring were some of the first custom builders to utilize high-tech innovative design and technology in each creation. Among being one of the first shops to chop classic muscle cars to change the lines, make wide-body builds, use unusual industrial materials for interior designs, integrate CAD for the design process and 3D printing for parts, the brothers were also the first in making custom billet parts in-house.

Much of what theyre known for is now standard use at multibillion-dollar OEMs building concept cars. But, for a tiny shop in Spring Green, Wisconsin to be the kick starter for these trends is something incredible. ENYO exemplifies what Ringbrothers is capable of.

Vehicle: Ringbrothers 1948 Chevrolet Loadmaster 1.5-ton PickupVehicle Name: ENYODesigner: Gary Ragle DesignsBuild Hours: 10,000 shop hours plus 2,000 design/CAD hours

Drivetrain

Engine: 510 cubic-inch tall-deck LS engine from Goodwin Competition Racing EnginesEngine Specs: 1,000 horsepower on 110 race fuelEngine Extras: Kinsler LS-Sprint eight-stack injection and Holley fuel management systemTransmission: Bowler Performance 4L80 automatic transaxle with torque tube

Exhaust

Header Details: Custom-fabricated one-off stainless headers with titanium side pipes fabricated with 58 feet of titanium pie-cut welds

Chassis & Suspension

Chassis: One-off Roadster Shop and AhlmanEngineering chassisFront Suspension:Cantileverindependent suspensionRear Suspension:Cantilever independent suspensionShocks:Customhlins TTXcoil overs with Swift Springs

Wheels & Tires

WheelManufacturer:Two sets of bespoke HRE Wheels911 centre lock wheels street and raceStreet Front Wheel Size:11×18-inchStreet Rear Wheel Size:13.5×19-inchStreetTire Manufacturer:Michelin Pilot Sports front,Bridgestone Potenza rearStreetFront/Rear Tire Size:315/30R18 front, 345/35R19 rearRace Front Wheel Size:13×18-inchRace Rear Wheel Size:15×18-inchRaceTire Manufacturer:Goodyear Racing Eagle G-19Race Front/Rear Tire Size:315/30RR18front,365/35R18rear

Brakes

BrakeManufacturer:BremboFront& Rear:Brembo GTS M6 brakes with six-pistoncallipersParkingBrake:E-Stopp emergency e-brake

Electrical

Wiring Harness: Painless Wiring

Exterior

Paint Manufacturer: BASF GlasuritPaint Color: Mythic Battle GreenPaint Booth: Global Finishing Solutions

Interior

Installation: Steve Pearson at Upholstery Unlimited and Gemini Technology SystemsGauges: Dakota Digital

Climate-ControlSystem: Vintage Air Gen II compact air-conditioning system

Corporate Sponsors

- BASF/Glasurit

- HRE Wheels

- Motul

- Flowmaster/Holley

Product Sponsors

- Ahlman Engineering

- ARP

- BASF Glasurit

- Brembo

- California Car Cover

- Dakota Digital

- DeWitts

- Dynamat

- GFS Global Finishing Solutions

- Miller Welding

- Mothers Polish

- MSD

- hlins

- Painless Wiring

- TMS Titanium

- XPEL Paint Protection Film

One-off Ringbrothers Parts

- Custom-designed and machined taillights

- Custom-designed brake light

- Custom-designed and machined fan shroud and covers

- Custom-designed 18-part gear shifter (titanium)

- Custom-designed and machined badging

- Custom-designed and machined pedal assembly and pedals (titanium)

- Custom-designed interior door pulls

- Custom-designed and machined suspension components

- Custom-machined exhaust cutouts

- Custom-designed and machined headlight heat sink caps

- Custom-machined hood hinges

- Custom-machined box side trim pieces

- Custom-designed roll bar mounts and clamps

- Custom-designed tube mounts

- Custom-designed leather embossing tool

- Custom-designed and 3D-printed mirrors

- Custom-designed steering wheel CNC machined by Sparc Industries

Major Modifications

- AutodeskAlias CAD-designed chassis by Scott Ahlman, designer of the 2005 Ford GTchassis, in conjunction with Roadster Shop engineers and fabricators

- Originalsteel cab narrowed 4-inches, chopped 4-inches, lengthened 2-inches, wedge cut2-4 inches through the cab

- Extensive useof carbon-fibre components including a single-piece carbon-fibre belly pan, grill,diffusers, exterior doors, hood, bedsides, spoiler, dashboard, torque tube,brake ducts, side air intakes, fan shrouds, roof interior, door panels, seats,and fire extinguisher mount.

- Clam-shelloperating hood with electromagnetic latches

- Open bed withexposed suspension, battery, rear-mounted radiator, air jack safety clamps

- Customstainless-steel gas tank by Ricks Tanks

- Custom-sizedsplit-glass windshield

- Powered custom-sizedside and rear glass

- InstalledNuke Performance air jack system for quick wheel and tire changes

- Nickelplating by AIH Chrome