Marsh Roadster The south African Monocoque Cobra

The MarshRoadsterstarted around 2017 when Marchand Ochse fulfilled a childhood dream of building his own AC Cobra. He says. ” I purchased the kit and then my architectural background with design and detailing very quickly came to haunt me. I realized that I’m not going to get the detail and the design that I would get if I did it myself. The result was that I explored all sorts of options in terms of where I could go locally to get it done.

” I soon realised that if I wanted to achieve specific quality, excellence and detailing, I would have to go down the road of manufacturing my own custom design, starting from the structure up. And, yeah, that’s where I am essentially today.”

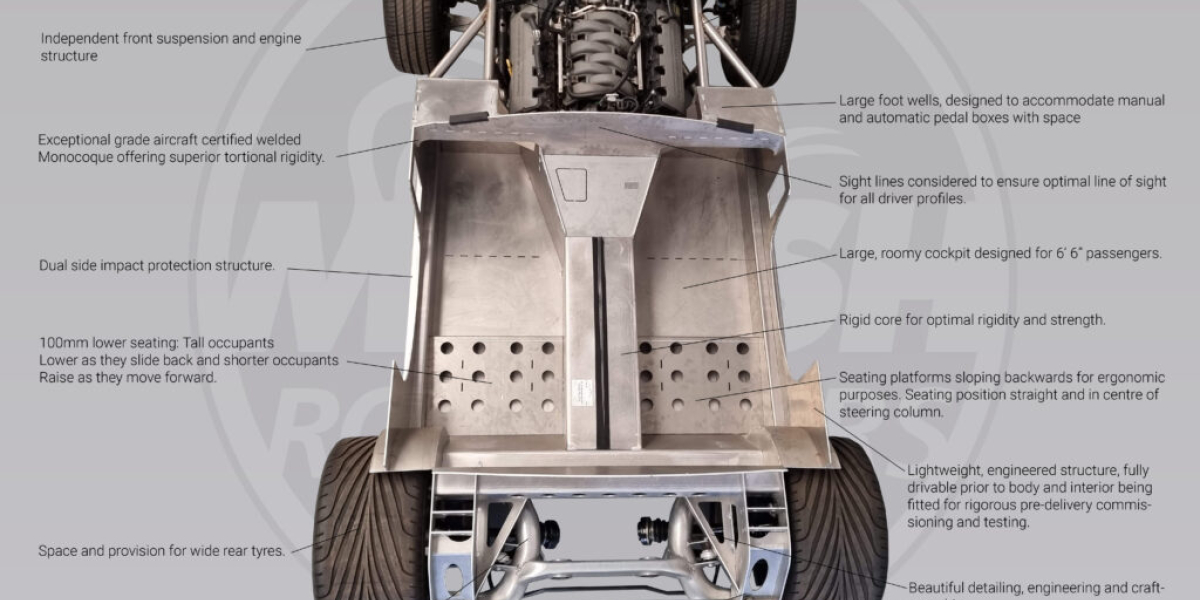

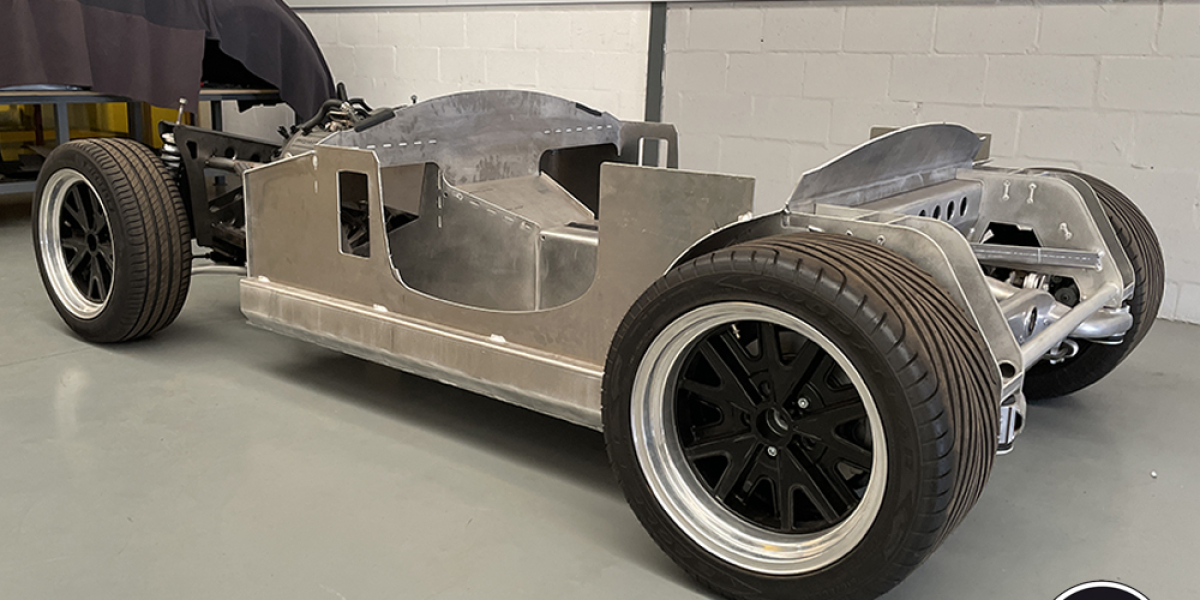

Marchand did quite a bit of research as to what is out there in terms of sports cars in general. He realized that the traditional ladder frame chassis had fallen out of the realms of sports cars some time ago. Now, naturally, people were going for this ladder frame chassis based upon the traditional design and detailing of the vehicles in question. However, it didn’t sit well with Marchand in terms of the issues that came with those chassis, namely their driveability, and their strength.

Basic ergonomics, as the biggest thing about these vehicles is that as a tall driver, your cockpit is pretty cramped. You’ve got a big V-eight engine sitting next to your foot and there’s only so much space you can create.

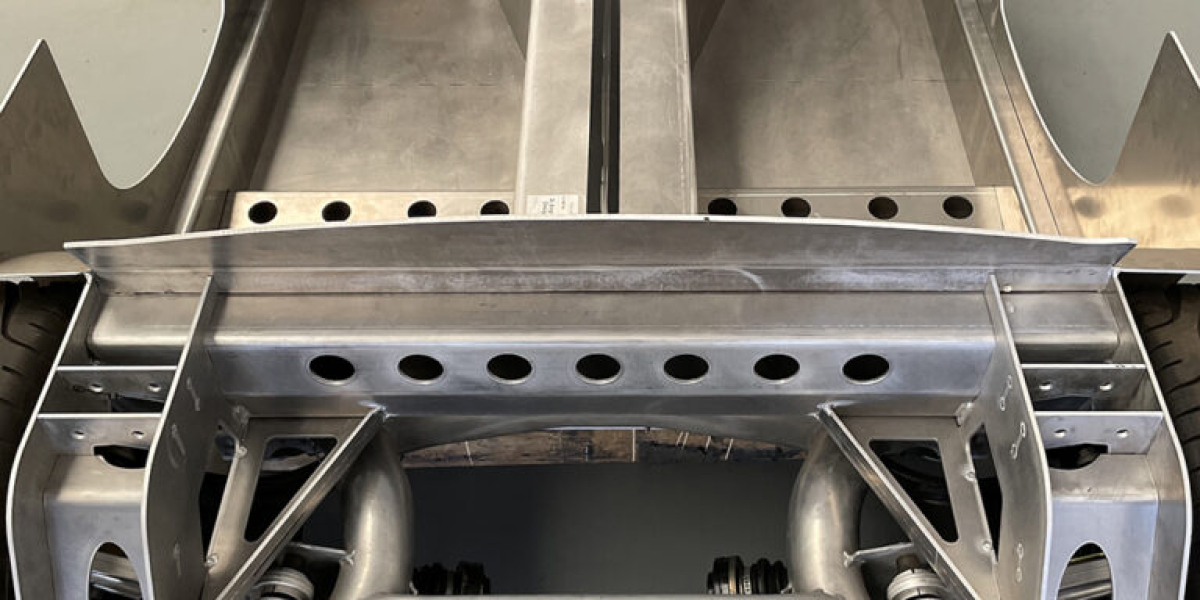

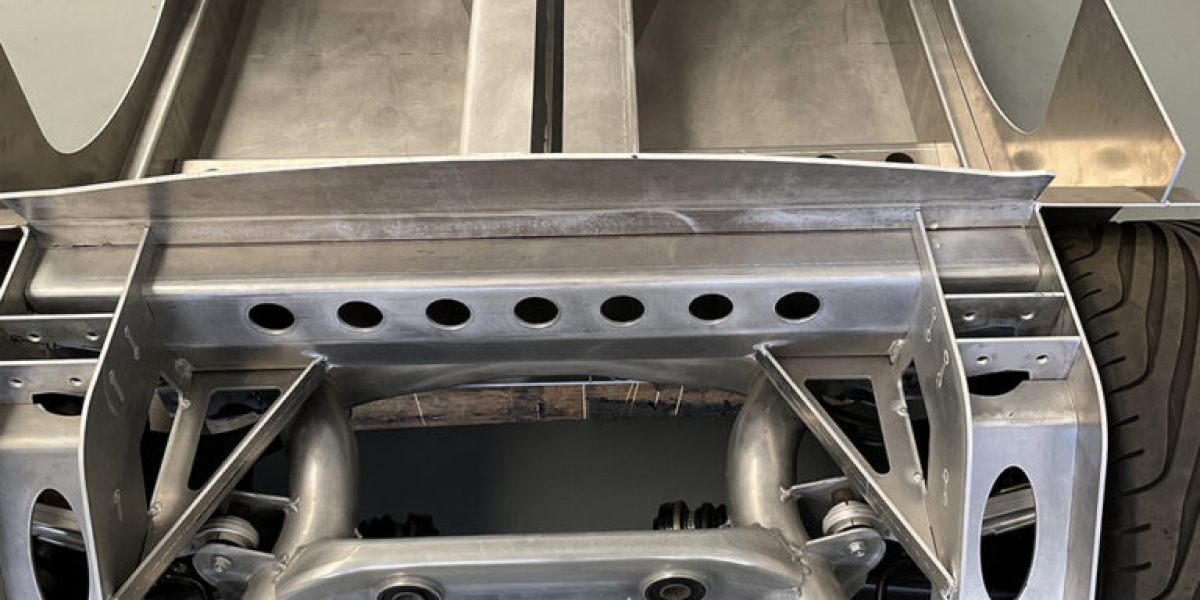

By coincidence Marchand, met up with Jean Fourie, who has a rich pedigree in designing these particular types of chassis. Being the monocoque chassis who came in my part, the monocoque chassis has a multitude of advantages. They’re very difficult to manufacture and that’s why a lot of people don’t go down that road. Together Jean and Marchand went through a tireless design episode or procedure of trying to develop and define what it is they don’t want in the vehicle and what it is they do want in the vehicle.

The primary thing really is safety as well as, ergonomics. The monocoque chassis is a tub-like structure that forms the backbone of the vehicle itself. And, as a result, you are sitting in this monolithic structure that is now about 100 mm lower than what you would have in a normal chassis-type scenario.

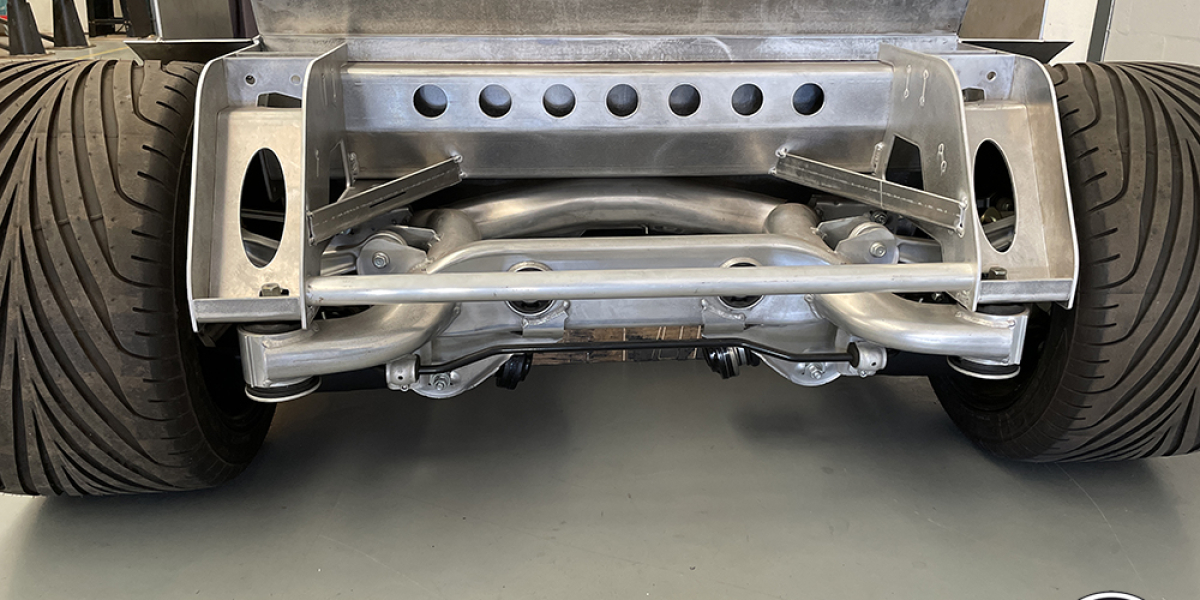

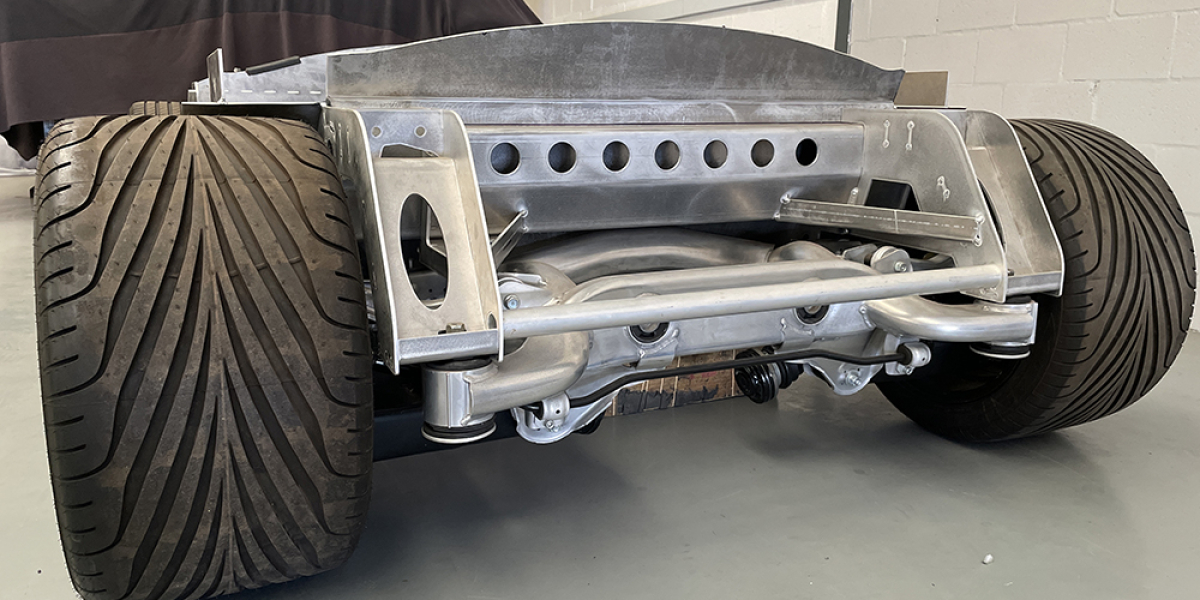

Furthermore, the suspension is an all aluminium OEM suspension type, which is coming from the BMW range. The purpose of OEM is purely from an export perspective because a lot of countries will not allow a custom-made suspension into their countries. And the principle is a lightweight, fully exportable vehicle that can be taken into any country.

The bodies are made locally and they’re made from a very high-grade resin. Its primary property is heat resistance, not just from the sun, but also from the heat that the engine bay creates. It’s less likely to break down, and when sprayed, it actually gives you a very good finish.

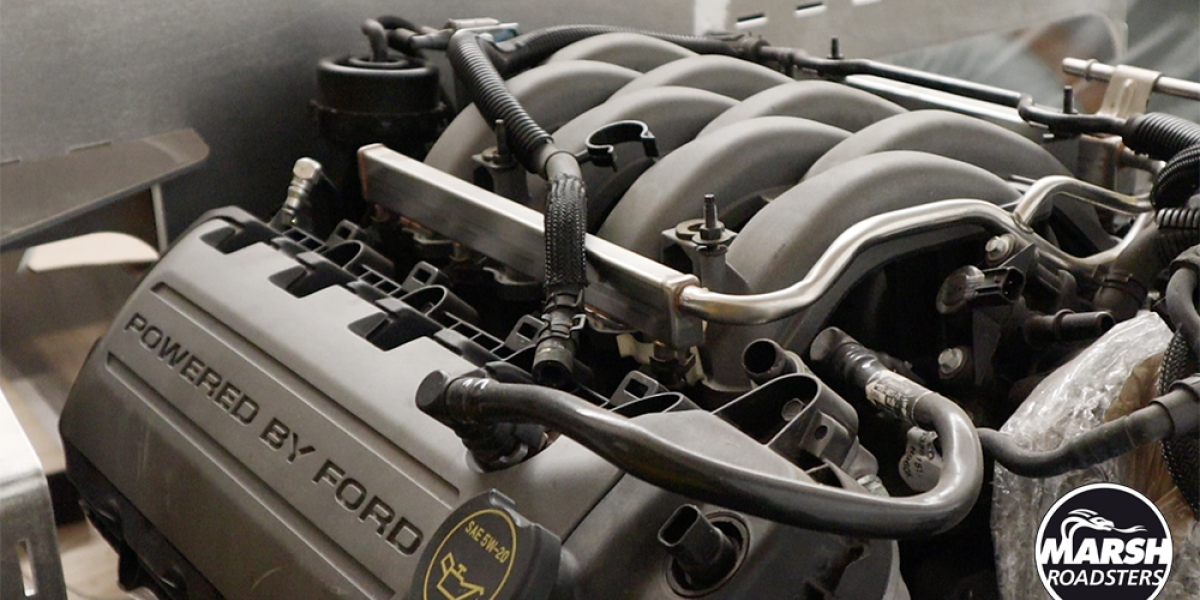

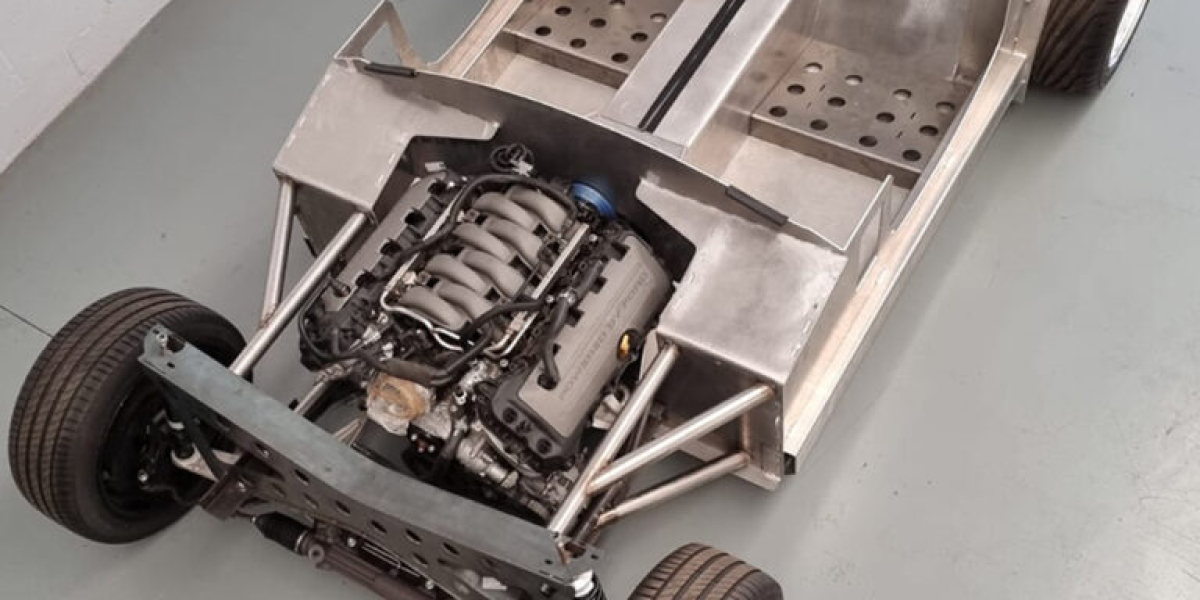

The prototype vehicle is going to have a Coyote five-litre Coyote motor. The Coyote engine is extremely large in size, together with this manual gearbox. The other reason they are going that route is purely from an export point of view when it comes to emissions. Which we believe is something that every country in the world in the years to come, is going to be very sensitive of. However, clients do have the option of other more traditional motors like a 302 or 351 Ford V8.

The vehicle doesn’t just take the Ergonomics into account, but it’s more to do with the overall design of the vehicle. Every single part of that car is being considered, for example, battery boxes. It has a home, it stays in the car and it looks like the car is built around the battery box. Same with the fuse box. All the services, from electric to plumbing, are going to be concealed.

They are going to run within ducts, which form structural members of the vehicle. So when you lift the car up, you do not see any services apart from exhaust pipes.

The seating of the vehicle has addressed a lot of the age-old problems of what is historically skewed in a Cobra. Marsh has taken that and dealt with it. In all likelihood, Marsh is going to have the most spacious cockpit out of all the manufacturers. They have taken advantage of the monocoque chassis and what that actually delivers. Your sight lines are extremely important.

A lot of the time, taller people end up with their eyes either above or below the windscreen and they constantly have to duck. Roll bars also look incredibly hideous with tall people, where it sits lower than their heads. So all those little design features and all those design constraints have been taken into account in the overall design package.

The design of the car is such that the car can be driven without the body on it, which is quite a remarkable feature. The reason for that is, obviously, when the car has been commissioned, you can take it on a racetrack or you can take it for a test drive. And essentially, you can set that car up to suit your needs. Whether you want it to be a track car, whether you want it to be a road car, all four corners can be set up to suit your specific needs. We work very closely with our customers from day one.

We go through a design presentation process where the client gets a package with information. Right from the colour through to the taillight type. And that forms a build sheet of the car. So essentially, you know exactly what you’re getting from the get-go. It’s clearly defined, and you’ve got a package at the end of the day that suits your specific needs rather than that of a factory, with only one type of option.

Currently, intensive final design and detailing brushstrokes are being applied to dial in the overall structural design of the rolling and driving chassis. Extensive track and field testing will be carried out before final changes are made.

Quality and precision are seamlessly merging into an engineering work of art. This takes time and dedication. Follow us https://www.facebook.com/MarshRoadsters to keep track of the progress and launch dates.

For Updates please register at https://marshroadsters.co.za