Crafting Excellence: The Art and Heritage of Momo Steering Wheels

The Heritage of Momo:

Founded in 1964 by Italian race car driver Gianpiero Moretti, Momo quickly established itself as a premier name in motorsports. The name "Momo" itself is derived from Moretti's initials and his hometown of Monza. From its inception, Momo became a symbol of precision, performance, and a passion for racing that resonates with automotive enthusiasts worldwide.

-

Craftsmanship: Momo steering wheels are crafted with meticulous attention to detail, reflecting the brand's commitment to craftsmanship. Skilled artisans use a combination of traditional techniques and cutting-edge technology to create steering wheels that not only meet rigorous performance standards but also exude a sense of artistry.

-

Materials: Momo's dedication to excellence is evident in the materials chosen for their steering wheels. High-quality materials such as top-grade leather, carbon fiber, and aluminum are meticulously selected to ensure durability, comfort, and a tactile driving experience.

-

Design Innovation: Momo is renowned for its innovative and ergonomic designs. Steering wheel shapes, grips, and button placements are carefully considered to enhance the driver's control and comfort during high-performance driving. Each design undergoes rigorous testing to ensure optimal functionality and aesthetic appeal.

The Process of Making Momo Steering Wheels:

-

Conceptualization: The process begins with the conceptualization of a new steering wheel design. Momo's design team combines creativity with functional considerations, envisioning a product that not only looks exceptional but also performs at the highest level.

-

Material Selection: Once the design is finalized, the team selects the appropriate materials. Whether it's the supple feel of leather for a luxury model or the lightweight strength of carbon fiber for a racing edition, each material is chosen with performance and aesthetics in mind.

-

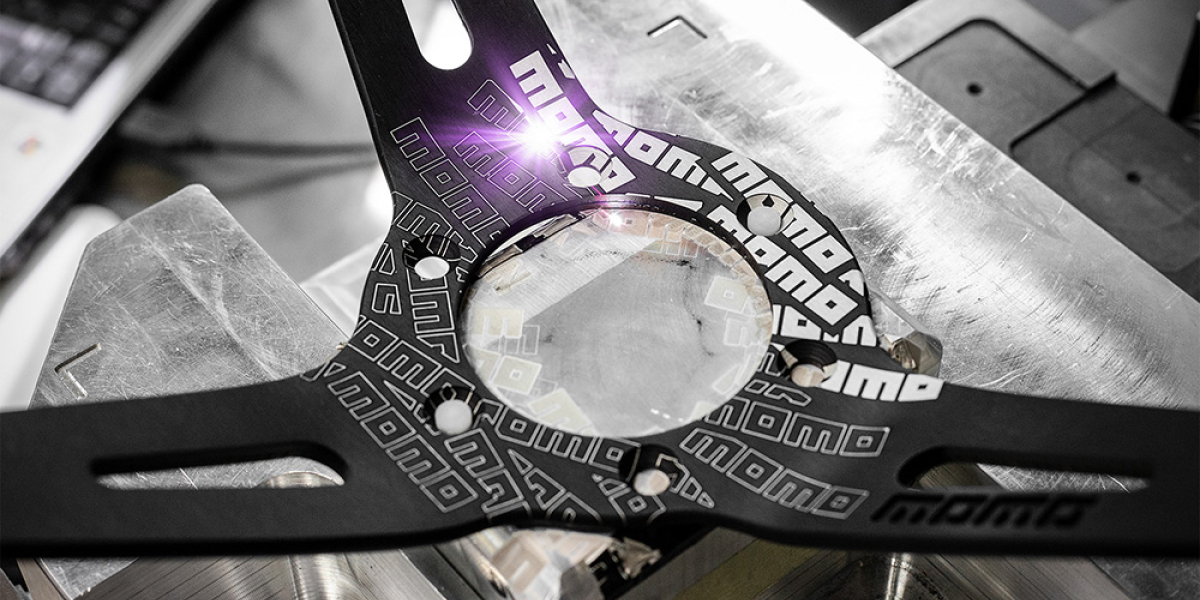

Precision Engineering: Momo leverages state-of-the-art engineering techniques to manufacture steering wheels with precision. Computer-aided design (CAD) and computer numerical control (CNC) machining ensure that each component meets exact specifications, contributing to the overall quality and consistency of the product.

-

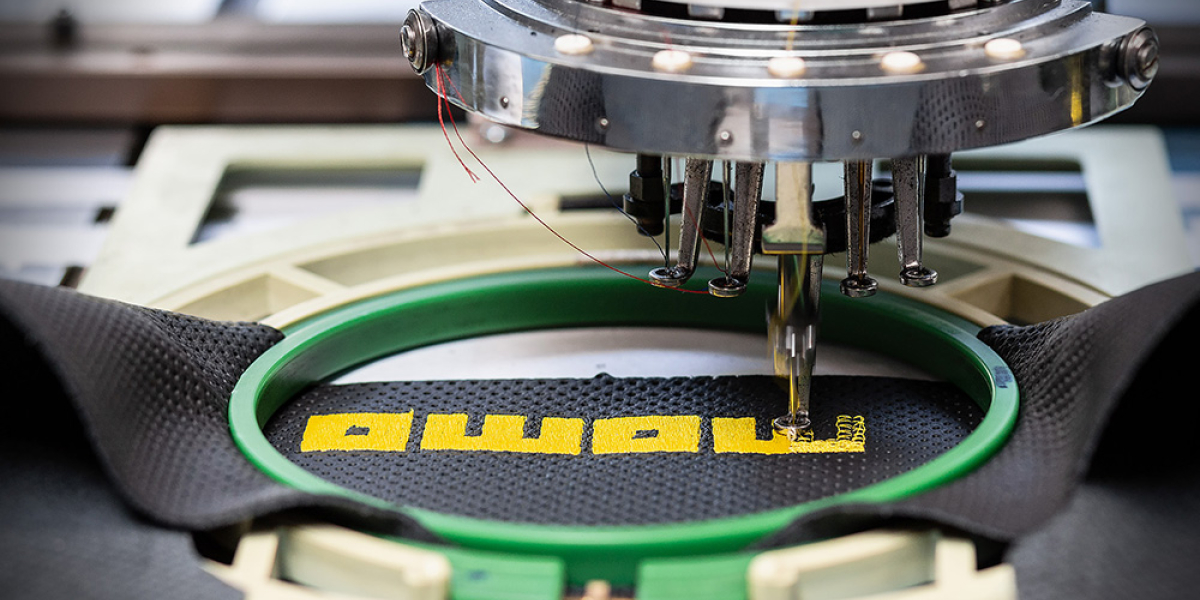

Handcrafted Assembly: While modern technology plays a significant role, Momo steering wheels retain an element of handcrafted artistry. Skilled artisans hand-assemble each steering wheel, paying close attention to details like stitching patterns and the placement of emblematic Momo logos.

-

Quality Control: Before reaching the hands of consumers, each Momo steering wheel undergoes rigorous quality control measures. Performance, durability, and aesthetic criteria are scrutinized to ensure that the final product lives up to the brand's legacy.

Momo steering wheels stand as a testament to a rich heritage rooted in the world of motorsports. The fusion of craftsmanship, innovative design, and a commitment to quality positions Momo as a leader in the automotive aftermarket. Beyond being functional components, Momo steering wheels are a driving force, connecting drivers to the road with a blend of tradition and cutting-edge technology.